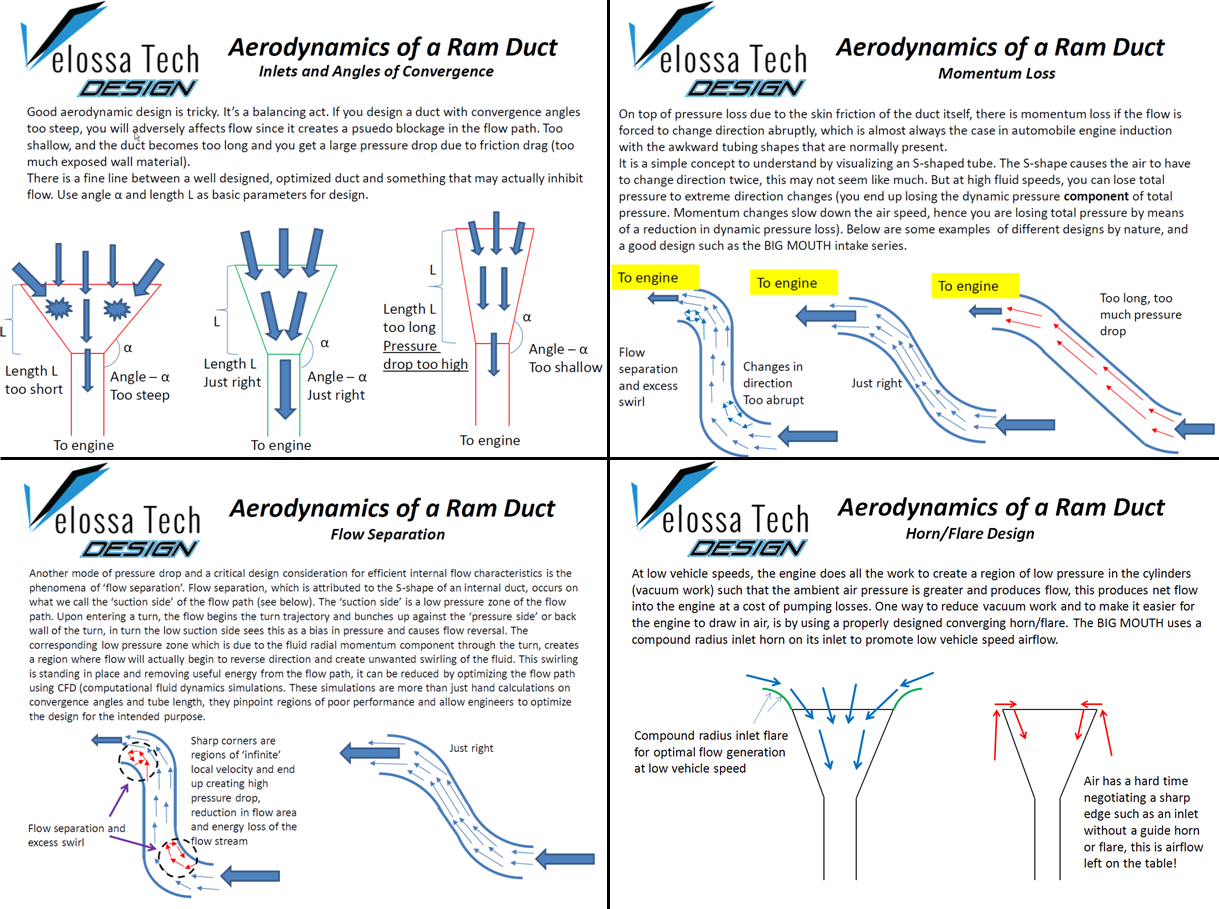

Velossa Tech ram air intake snorkels go through rigorous aerodynamic design, development, and testing to obtain the optimal shape for maximum performance. Maximum performance, in engineering terms, means minimum pressure drop (loss of pressure from the point the air enters the duct until the point it exits the duct and transfers air to the airbox). And on top of minimum pressure drop, the duct must have a net positive pressure gain while the car is in motion. Obtaining a net positive pressure gain is paramount to any optimized ram air intake. If the duct exhibits pressure drop that is too high, then any advantageous increase in pressure at the duct inlet obtained as the car is moving through the air at speed, is lost due to pressure drop, and the net gain is not realized.

There are a few tricks aerodynamicists use to create ducts that are low pressure drop, at the same time have seemingly counterintuitive geometry, such as direction change, added pipe length, or converging flow sections. These geometric features are necessary of course, otherwise there would be no duct in place to begin with. At first, these geometric features may seem like they would inhibit flow. This assumption would be correct if the inlet pressure to the duct was ambient, but it is not. The inlet pressure to the ram air duct is greater than ambient, hence the term. So that gives us wiggle room to work with to optimize the duct for pressure recovery while minimizing pressure drop.

If the sum of those pressure drops due to direction change, pipe length, etc. are less than the inlet pressure obtained once the car is in motion, then the ram air intake will exhibit a net positive performance (pressure) gain. And as a result, an increase in air mass flow, or a decrease in wastegate duty cycle if your car is turbocharged and has a load-targeting tune.

Shown below is a 4-block diagram of the basic starting point for proper high-pressure ram air intake snorkel design. We can’t go too in-depth on the theory behind aerodynamic design as that would be a 4-year course in itself! However, this high-level conceptual representation is a good way for one to understand that tuning a ram air intake is like tuning a piano. It is an iterative process that requires experience understanding the nuances of compressible flow where things can go wrong.

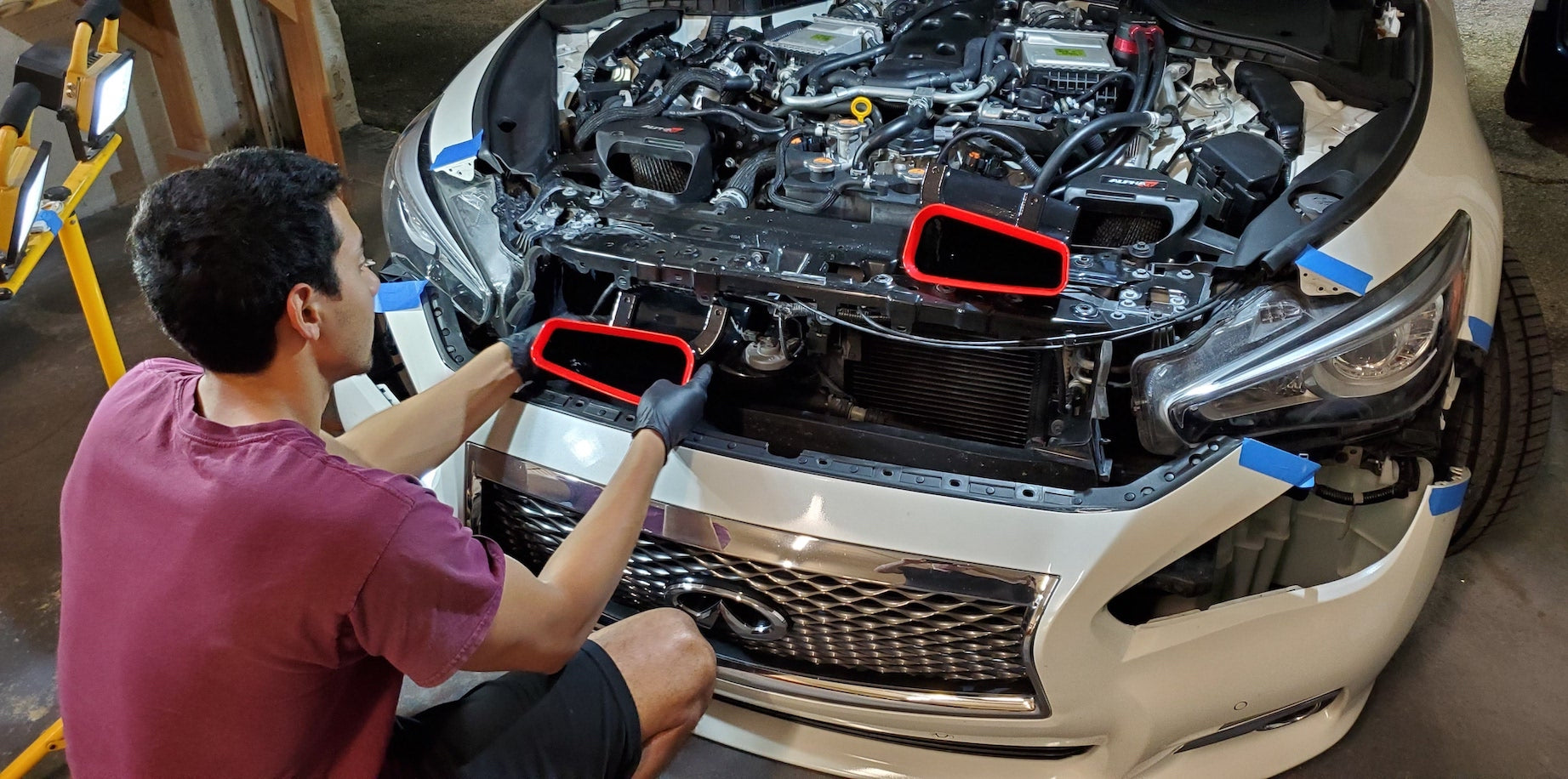

The design process begins with obtaining the car in question. We like to work with cars that have nice open grilles, where the frontal high-pressure zone is accessible to the ram air intake. Putting a ram air inlet behind a ‘solid’ or sealed bumper will not be the proper use of the ram air since those bumper styles would be blocking the ram air inlet from scavenging high-pressure, high-speed air.

For this example, we will focus on one of Velossa Tech’s latest ram air intake snorkel designs, the Infiniti Q50 and Q60 dual BIG MOUTH ram air intake snorkels.

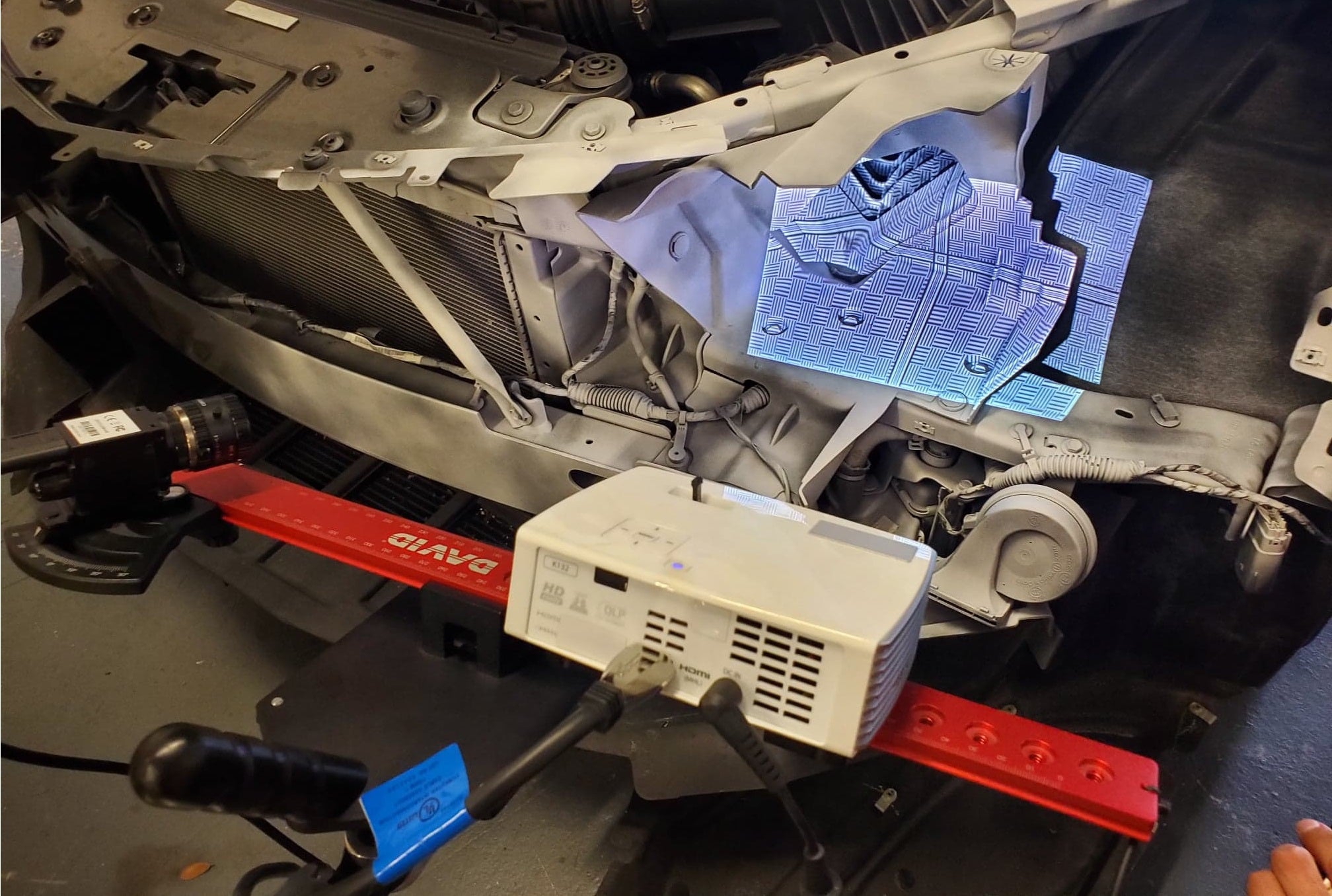

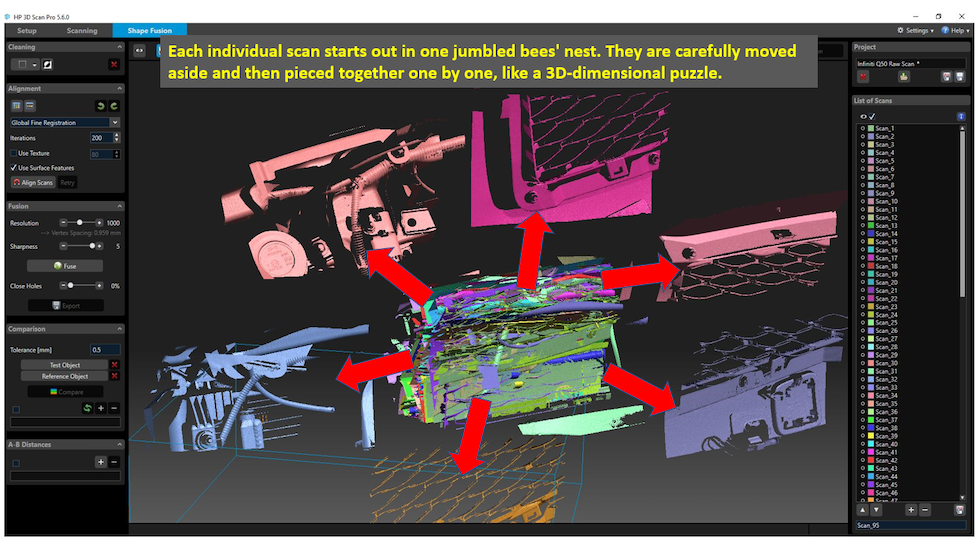

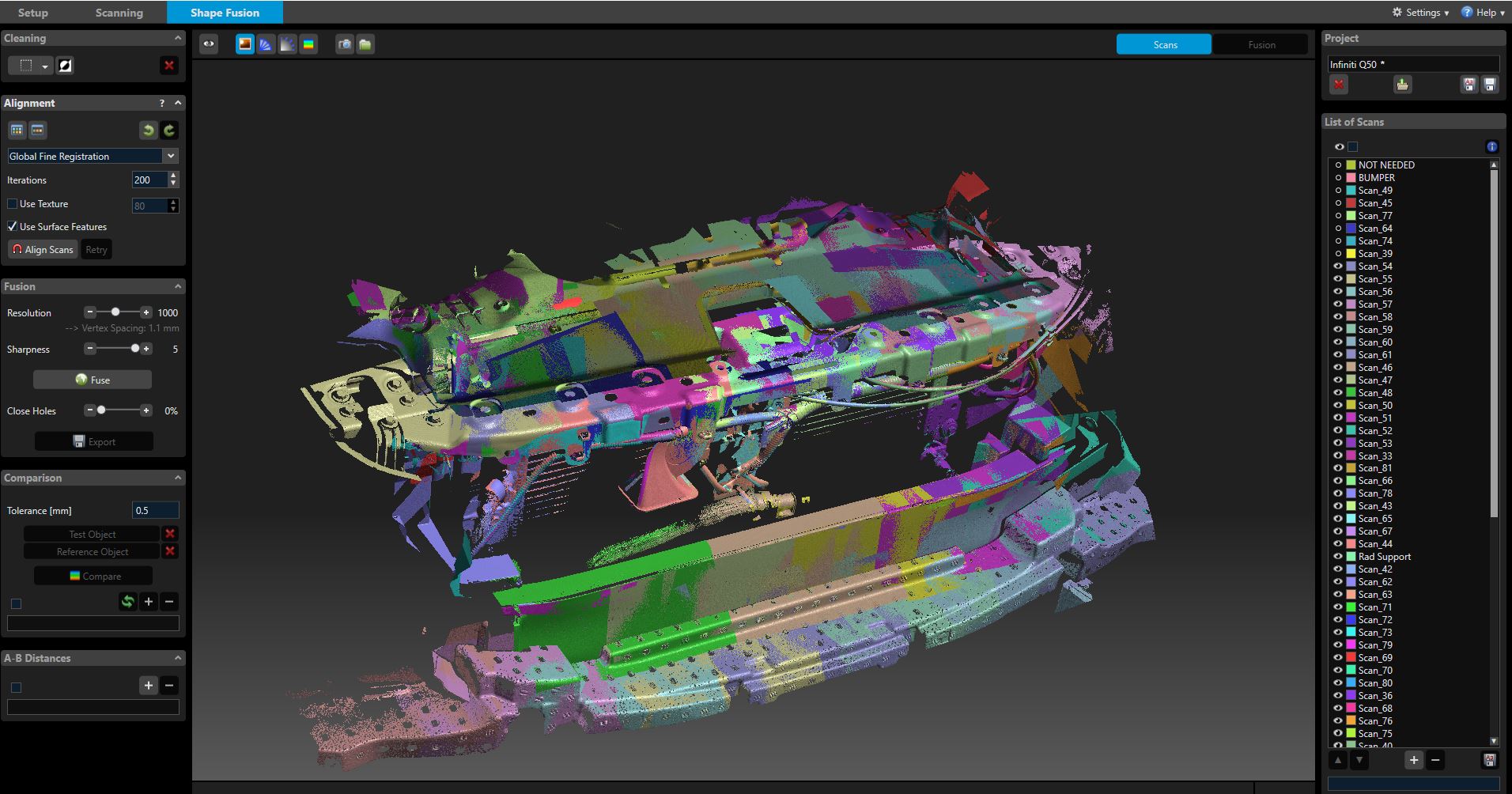

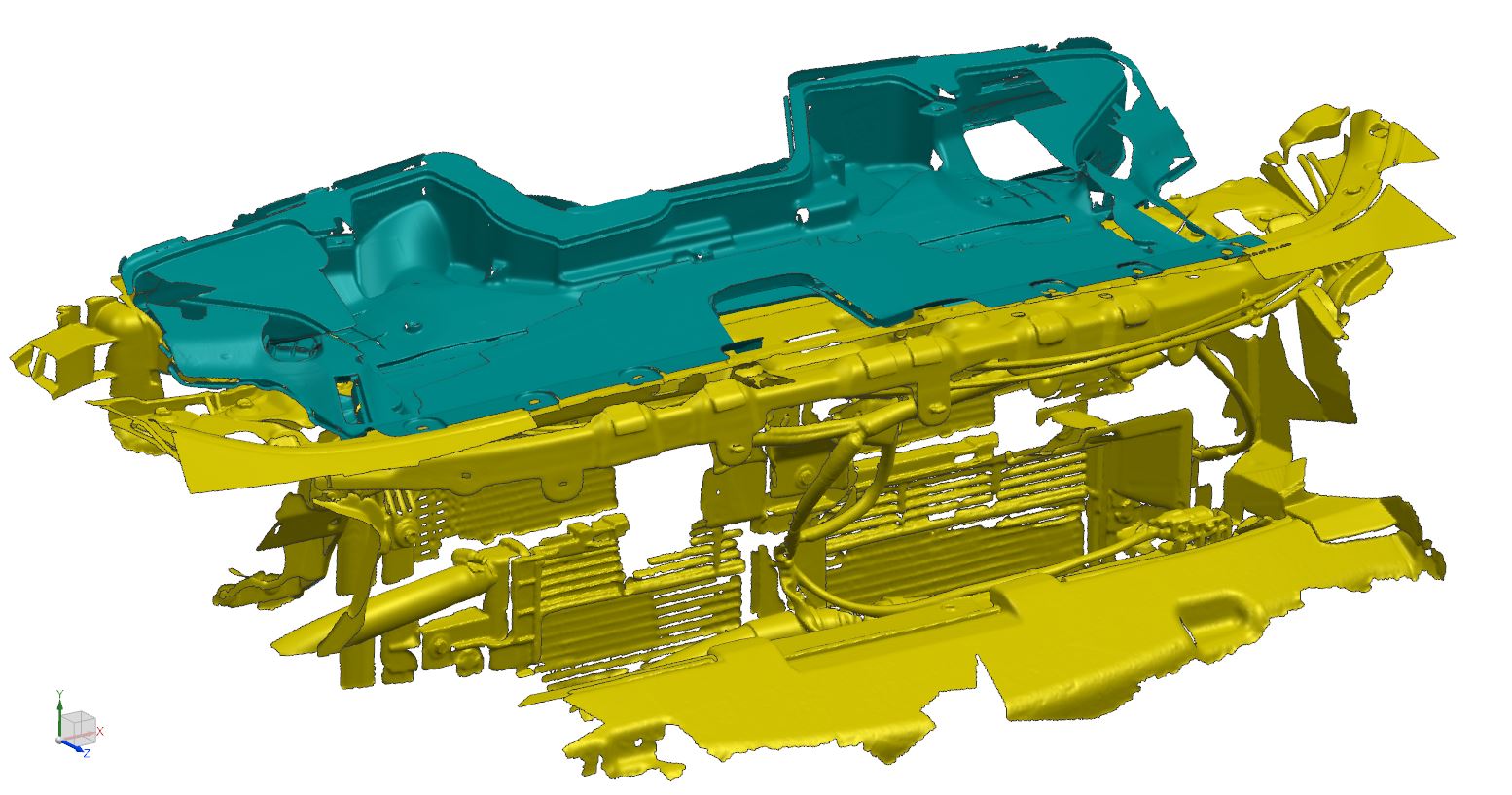

We start by using our structured light 3D-scanner to obtain geometric data. Shown below is a part of the 3D-scanning process, as we scan we start to get an idea of the route the flow path must take.

Scanning using this method is like taking pictures, except these pictures are 3D-point clouds that are connected through a mesh of triangles. Each scan is a separate picture that doesn’t know what orientation it must be in, or what part of the car it ‘belongs’ to. Work then goes into orienting these snapshots.

This can be a tedious process if we take many scans, sometimes we need to merge over 150+ snapshots!

After the merge and scan quality checks out, we import this data into our CAD modeling program and begin to design the duct, knowing what enemy we must combat: pressure drop.

On top of the flow path design, figuring out how to fasten the duct (and make it easy to install) is the next most important thing. Without an easy way for the customer to install the part, the part then loses value. Our design intent has always been performance/aesthetics/ease of installation. We have a ‘no-cutting’ policy on our products. In one rare instance, we did make a product where trimming was necessary, on the Ford Fusion BIG MOUTH ram air intake snorkel.

In all other cases, our installation intent, flow path design, and aesthetic beauty are what make us a world leader in this segment. Below, you’ll see the rigorous design attempts where we go back and forth from CAD modeling to CFD (computational fluid dynamics) to obtain the optimal flow path, optimal installation methods, and best-looking final product.

Eventually we settle on a design that meets our criteria. Sometimes this takes only days, sometimes it takes months. We don’t stop until it gets the stamp of approval for the “BIG THREE” - performance, ease of installation, aesthetics.

Prototype testing takes place during the design iteration phase; as we design, we test fit to ensure that installation criteria are being met along the way.

Sometimes we must go through a dozen test fits to get it just right. If the product is even 1 millimeter off, we reschedule a test fit with our locals and re-make the prototype. NO corners are ever cut at Velossa Tech Design.

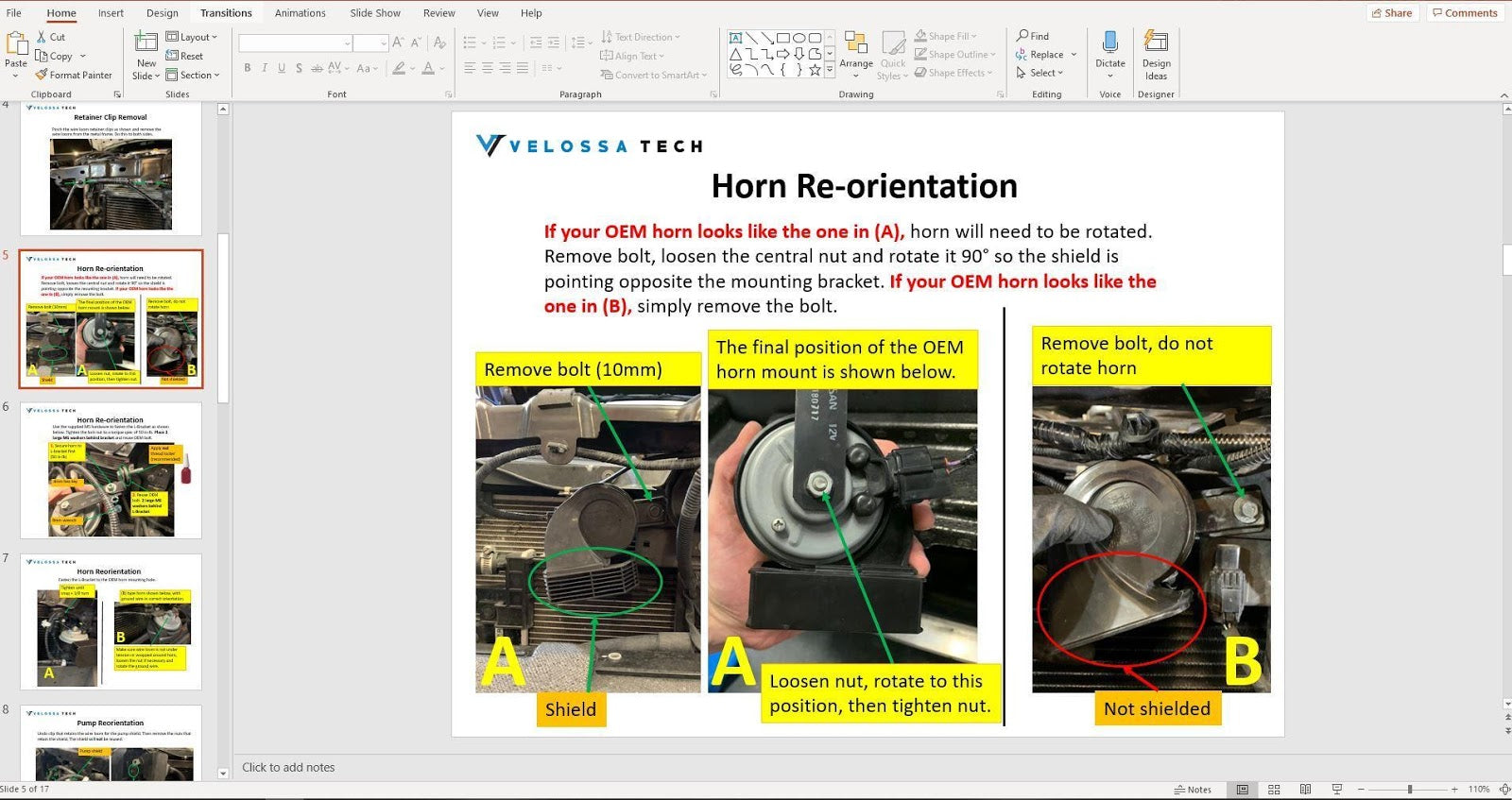

When the final product is complete, and the “BIG THREE” are all met, the instruction manuals are written by our team of engineers. Full color and downloadable manuals are available for all products right on our website.

The final product is then optimized for production and we proceed to give it the green light. It feels great to say something was designed and manufactured in the USA right here at Velossa Tech Design. We hope you enjoyed learning more about the process that goes into making our BIG MOUTH ram air intake snorkels!

Share:

Velossa Tech Shifts Gears to Produce Personal Protection Equipment and Ventilator Splitters

Benefits of a Ram Air Intake Snorkel for the Toyota Supra MK5